: These documents are usually employed and completed with the manufacturing Division. Batch records deliver step-by-action Guidance for production-related duties and actions, Aside from which includes regions to the batch report alone for documenting such tasks.

Documents should have unambiguous contents: the title, mother nature, and objective ought to be Obviously mentioned. They ought to be laid out within an orderly trend and become straightforward to examine.

Raw substance screening: This important move involves analyzing the ingredients used in producing pharmaceutical solutions. It makes certain that raw materials meet the expected technical specs and therefore are free from impurities or contaminants that would compromise the caliber of the final product.

Process Qualification: Approach Qualification is meant to find a result of the method which will establish the capability to reproduce commercial production output. All through this process, all important excellent parameter is taken under consideration to make certain solution high-quality.

A certification of study (CoA) is definitely an Formal doc issued by a producer or provider that certifies the standard and purity of a particular merchandise, typically Uncooked products or concluded pharmaceutical products and solutions.

Listed here at JAF Consulting, Inc., we fully grasp the complexities and problems that come with retaining GDP compliance. We aim to aid businesses navigate these demands, empowering them to obtain the best criteria of information integrity and excellent administration.

Batch packing records (BPR) are documents that give a detailed document of all packaging functions done for a particular batch of a product.

Excellent assurance (QA) performs a important part in ensuring that pharmaceutical products and solutions fulfill the essential top quality standards.

● Handwritten signatures needs to be distinctive to the individual and listed inside the signature register making sure that the signature is traceable towards the worried personnel (or contractor).

● The same is legitimate for Digital documents and information – language needs to be very clear and unambiguous.

The validation learn plan have to be summarized before describing the whole point in initiatives. These are the next details being A part of a protocol that is followed by all pharmaceutical industries.

The main purpose of QC should be to read more confirm and exam prescription drugs and medical equipment at numerous stages of production to ensure every products is of the very best high-quality. This method will involve immediate corrective steps to rectify defects and could involve multiple iterations for steady high quality improvement.

Validation is definitely the artwork of designing and practising the developed steps together with With all the documentation. System validation emphasize on procedure designelements and maintaining system Command for the duration of commercialization andcommunicate that method validation is undoubtedly an ongoing application and alignprocess validation activities with product lifecycle. Method validation alsoemphasizes the purpose of objective steps and statistical equipment & analysesand emphasizes awareness, detection, and control of variability and givesassurance on reliable of read more excellent/productiveness all over life cycle of product or service.

We have been making use of unique logbooks but some have only "done by" possibility or only "checked by" possibility and several have equally possibilities. It really is baffling. Could it be needed to have each "accomplished by" and "checked by" alternative in Logbook? ReplyDelete

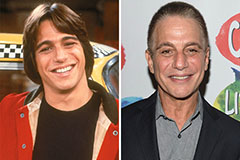

Tony Danza Then & Now!

Tony Danza Then & Now! Jennifer Love Hewitt Then & Now!

Jennifer Love Hewitt Then & Now! Barry Watson Then & Now!

Barry Watson Then & Now! Matilda Ledger Then & Now!

Matilda Ledger Then & Now! Karyn Parsons Then & Now!

Karyn Parsons Then & Now!